Introduction

Most warehouses are still managed as cost centres. The focus is on storing inventory, dispatching orders, and controlling expenses, while hidden inefficiencies quietly erode profit.

Inventory inaccuracies cause write-offs. Slow picking delays shipments. Overstock locks working capital. Underused labour increases per-order cost. These losses rarely appear clearly in reports, which is why warehouses keep absorbing cost instead of creating value.

Leading organisations are changing this approach.

They are treating the warehouse as a performance engine, not just storage space.

With the right ERP design, inventory accuracy improves, fulfilment speeds up, and operational efficiency turns into measurable profit. This is where Odoo enables warehouses to move from cost control to margin impact.

Key Takeaway

- Warehouses lose profit through hidden inefficiencies, not storage costs

- Inventory inaccuracies, slow fulfilment, excess stock, and rework quietly erode margin

- Treating the warehouse only as a cost centre hides its impact on revenue and cash flow

- Odoo enables real-time inventory accuracy and system-guided warehouse execution

- Faster, first-time-right fulfilment directly protects revenue and customer trust

- Better stock control frees working capital and reduces write-offs

- When designed correctly, ERP turns warehouse efficiency into measurable profit

In this article, you will see how Odoo helps warehouses reduce hidden costs, improve performance, and contribute directly to business profitability, and how Entrivis Tech designs warehouse systems around outcomes rather than features.

Why Warehouses Are Still Treated as Cost Centres

Most warehouses were never designed to drive profit. They evolved to store inventory and ship orders, not to optimise margin. That mindset still shapes how systems, metrics, and decisions are made.

Layouts and processes are often built around where goods sit instead of how efficiently they move. This slows fulfilment and increases handling cost per order.

Hidden costs make the situation worse. Rework, picking errors, excess handling, and idle labour rarely show up clearly in reports, so inefficiencies repeat every day.

A lack of real-time visibility compounds the issue. Decisions rely on delayed data, meaning problems surface only after cost and service levels are already affected.

An ERP-driven approach changes this lens by treating warehouse operations as a system that directly influences revenue, working capital, and customer experience.

The Hidden Profit Leaks Inside Most Warehouses

Warehouse losses rarely come from one major failure. They come from small inefficiencies that repeat daily and quietly erode margin.

Inventory inaccuracies force businesses to overstock as a safety buffer or write off losses later. Both outcomes damage working capital.

Inefficient picking paths and manual processes slow fulfilment and raise labour cost per order. Without demand visibility, excess and dead stock accumulate.

Labour inefficiencies increase rework and repeat handling. Missed delivery commitments then lead to penalties, expedited shipping, and damaged customer relationships.

Individually, these issues look operational. Together, they form a profit drain that is hard to trace without a connected system.

How Odoo Reframes Warehouse Operations

Odoo shifts warehouse management from reactive handling to controlled execution. Instead of updating stock after movement happens, the system guides how inventory should move.

Real-time inventory accuracy removes the gap between system data and physical stock. This eliminates many write-offs and emergency purchases.

Picking, putaway, and routing follow defined rules rather than individual judgement. Travel time reduces, errors drop, and congestion eases during peak hours.

Barcode-enabled execution enforces discipline without slowing work. Multi-location visibility prevents unnecessary overstocking and stock imbalances.

When designed properly, these capabilities reduce waste, protect margin, and support profitability.

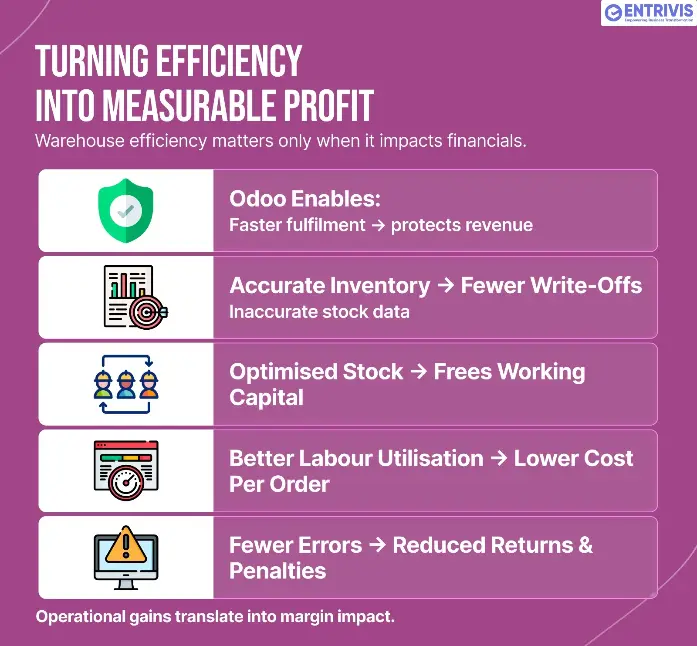

Turning Warehouse Efficiency into Measurable Profit

Efficiency matters only when it shows up in numbers.

Faster fulfilment protects revenue by reducing cancellations, penalties, and emergency shipping. Accurate inventory lowers write-offs and last-minute purchases.

Optimised stock levels free working capital and improve cash flow. Better labour utilisation reduces cost per order without increasing headcount.

Fewer errors and returns lower costs across logistics, customer service, and finance. This is where performance begins influencing margin.

KPIs That Change When Warehouses Run on Odoo

- Inventory accuracy improves through real-time stock updates

- Fulfilment cycle times shorten and become predictable

- Picking accuracy approaches first-time-right execution

- Returns and rework reduce significantly

- Inventory turnover improves, releasing trapped working capital

- Cost per order stabilises even as volumes grow

- Leadership gains control through data instead of intuition

Real-World Warehouse Scenarios Where Odoo Delivers ROI

Odoo delivers the most value as warehouse complexity increases.

High-SKU manufacturing environments benefit from structured location control and movement rules that reduce handling time and errors.

Distribution centres gain speed and consistency during peak periods through guided picking and packing.

Multi-location operations avoid stock imbalances with a unified inventory view. Fast-growing businesses replace fragile spreadsheets with controlled processes.

In each scenario, ROI comes from consistency, visibility, and control rather than automation alone.

Why Implementation Design Matters More Than Features

Most warehouse ERP projects fail not because software lacks features, but because systems are configured without understanding real workflow.

If picking routes do not reflect actual movement, systems introduce friction. Over-engineering adds complexity that teams struggle to adopt.

Good design starts with outcomes. Only after identifying where time, money, and accuracy are lost should configuration begin.

This is why implementation experience matters more than feature lists.

How Entrivis Tech Helps Turn Warehouses into Profit Centres

Entrivis Tech approaches warehouse transformation as an operational design challenge, not a software task. The focus is on how work actually happens on the warehouse floor and how efficiency translates into profit.

- Analyses real inbound, storage, picking, and dispatch workflows

- Configures Odoo to match real operations, not theoretical processes

- Designs location structures, movement rules, and automation levels carefully

- Embeds performance measurement for continuous improvement

- Refines systems as operations scale instead of rebuilding them

The result is a warehouse that scales efficiently while maintaining control and profitability.

Common Mistakes in Warehouse ERP Adoption

Warehouses often fail to see ERP benefits not because of the system, but because early decisions block efficiency and adoption. These mistakes quietly undermine ROI.

- Automating broken processes instead of fixing root issues

- Designing workflows without floor-level operational insight

- Tracking KPIs without using them to drive improvement

- Treating ERP as an IT project rather than an operational transformation

Avoiding these mistakes keeps ERP aligned with warehouse realities and focused on measurable performance gains.

Conclusion

Warehouses influence profitability far more than most organisations realise. Delays, errors, and inventory mismatches quietly erode margin and cash flow when warehouses are treated only as cost centres.

Odoo brings real-time visibility, guided execution, and measurable performance into warehouse operations. When systems are designed around flow and outcomes, efficiency becomes a financial advantage.

Entrivis Tech helps organisations build warehouses that are faster, leaner, and predictable. Efficiency stops being hidden cost and starts becoming sustained profit.

TF 01, Raama Esquire, Laxmipura,

TF 01, Raama Esquire, Laxmipura,  hello@entrivistech.com

hello@entrivistech.com

+91 991 306 8606

+91 991 306 8606

How Odoo Can Turn Your Warehouse into a Profit Centre (Not Just a Cost Centre)